Product Description:

Product Description:

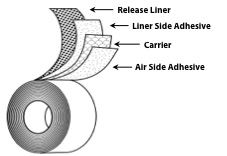

A two sided, high tack, high shear, 8-mils total thickness with an aggressive acrylic adhesive system on a 1-mil PET film and a blue PP liner.

Product Use:

488M is the right choice when high tack, higher temperatures and high shear properties are needed. Converter friendly liner allows for precise die cutting and slitting needs. Exceptional performance for wood, metals, rubber and plastic extrusions.

Applications:

- Mounting of rubber parts in the transportation industry

- Fastening components in the electronic market

- Attaching trims in construction and furniture market

- Point of Purchase and Signs mounting

- Excellent for EPDM and rubber extrusions

- Mounting of ABS plastic and other rubber and plastic parts in Automotive Industry

Adhesive Family

400 High Performance Aggresive Acrylic Adhesive Tape System

Release Liner

Blue Polypropylene Liner

Carrier/Backing

1 mil Clear Polyester Film

Tape Construction

Double Coated PET Film Tape

Adhesive Liner Side

Acrylic

Adhesive Thickness - Liner Side (Mils)

3.5

Adhesive Exposed Side

Acrylic

Adhesive Thickness - Exposed Side (Mils)

3.5

Peel Exposed Side

160

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil dead soft Aluminum Foil. 24 Hour Dwell.

Peel Liner Side

180

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil dead soft Aluminum Foil. 24 Hour Dwell.

Shear Exposed Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 500 grams/Sq.Inch @ 150oF.

Shear Liner Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 500 grams/Sq.Inch @ 150oF.

Service Temperature

-30

°F to

250

°F

Note: Data is based on limited testing and under no load.

Roll Weight

Note: Theoretical number only. The actual roll weight may vary.

Tape Thickness (without release liner)

8.0 mils

Note: Theoretical number only. Does not include Release Liner. The actual Tape thickness may vary.

SDS Note: If the specific product is not listed in the appendix of the provided "Article Exemption Letter", please contact your sales/account representative for a SDS.

Supplemental Peel/Shear Results

| Substrate | Dwell Time | Testing Method | Exposed Side Peel | Liner Side Peel | Exposed Side Shear | Liner Side Shear |