Product Description:

Product Description:

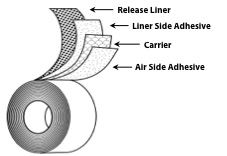

A 1/2 mil polyester film carrier with a different synthetic rubber based adhesive system on each side of the carrier. 1.8 mils Coated on the exposed side with a high peel, high shear rubber adhesive and 1.2 mils on the liner side with a low peel, high shear

Product Use:

This product was developed for use in the abrasives and polishing industries and laminates well to polishing or abrasive pads and disks and removes cleanly from the polishing tool when the polishing cycle is completed. 1711M uses a high quality rubber based adhesive system on the laminating or exposed side of the 1711M and a special high shear, moderate peel adhesive on the liner or user side of the product. The polyester film offers dimensional integrity to either narrow width slitting for shelf strip labeling or the die cutting of finishing pads or disks. The liner side exhibits little or no build up in adhesion after application. GENERAL USE: 1711M has found acceptance in areas where die cut abrasives, fabrics, and nonwovens are used. It's good adhesion to any flexible substrates as well as it's clean removability from lap surfaces has made it ideal for polishing pads, sanding disks, shelf strip labels, protective bumpers, floor graphics, magnetic vinyls, chalkboard replacement vinyls, and other applications where clean removability is important.

Adhesive Family

1700 Rubber Based Permanent Removable Bonding Tape System

Release Liner

80# White Densified Kraft

Carrier/Backing

1/2 mil Clear Polyester Film

Tape Construction

Double Coated PET Film Tape

Adhesive Liner Side

Rubber

Adhesive Thickness - Liner Side (Mils)

1.2

Adhesive Exposed Side

Rubber

Adhesive Thickness - Exposed Side (Mils)

1.8

Peel Exposed Side

290

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell.

Peel Liner Side

110

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell.

Shear Exposed Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Shear Liner Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Service Temperature

30

°F to

150

°F

Note: Data is based on limited testing and under no load.

Roll Weight

0.45 lbs/sq yards

Note: Theoretical number only. The actual roll weight may vary.

Tape Thickness (without release liner)

3.5 mils

Note: Theoretical number only. Does not include Release Liner. The actual Tape thickness may vary.

SDS Note: If the specific product is not listed in the appendix of the provided "Article Exemption Letter", please contact your sales/account representative for a SDS.