Product Description:

Product Description:

A high-peel, high-tack, moderate dead load acrylic adhesive film coated on both sides of a high quality polyester film.

Product Use:

353M exhibits excellent adhesion to a very wide variety of substrates. 353M also has good general purpose foam lamination, as well as good general purpose lamination to fabricated parts. 353M is ROHS compliant. General Use: For bonding and laminating to a wide variety of urethane foams including polyether, polyester and low perm foams. For bonding and laminating to a wide variety of cloths, vinyls, corks, papers, rigid and flexible plastics.

Adhesive Family

350 Aggressive Acrylic Adhesive Tape System

Release Liner

74# White Polycoated Kraft

Carrier/Backing

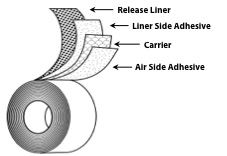

1/2 mil Clear Polyester Film

Tape Construction

Double Coated PET Film Tape

Adhesive Liner Side

Acrylic

Adhesive Thickness - Liner Side (Mils)

1.4

Adhesive Exposed Side

Acrylic

Adhesive Thickness - Exposed Side (Mils)

1.8

Peel Exposed Side

220

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell

Peel Liner Side

210

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell

Shear Exposed Side

4

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. 1 Minute Maximum Dwell.

Shear Liner Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. 1 Minute Maximum Dwell.

Service Temperature

°F to

°F

Note: Data is based on limited testing and under no load.

Roll Weight

0.5 lbs/sq yards

Note: Theoretical number only. The actual roll weight may vary.

Tape Thickness (without release liner)

3.7 mils

Note: Theoretical number only. Does not include Release Liner. The actual Tape thickness may vary.

SDS Note: If the specific product is not listed in the appendix of the provided "Article Exemption Letter", please contact your sales/account representative for a SDS.

Supplemental Peel/Shear Results

| Substrate | Dwell Time | Testing Method | Exposed Side Peel | Liner Side Peel | Exposed Side Shear | Liner Side Shear |

Bonding Study Results

| Manufacturer |

Material Description | Bonding Result | Notes/Comments |

Tested Industry Specifications

| Specification Type |

Specification Description |

Notes |

| Chrysler |

Chrysler PF-10770 (NC) |

Individual reports containing A2LA Accredited data can be provided |

|

| Ford |

Ford ESH-M11P19-B (3/93) |

Individual reports containing A2LA Accredited data can be provided |

|

| Ford |

Ford ESA-M11P19-A (1/79) |

Individual reports containing A2LA Accredited data can be provided |

|

| General Motors |

General Motors GM3622M (11/93) Type III |

Individual reports containing A2LA Accredited data can be provided |

|

| General Motors |

General Motors GM3622M (11/93) Type IV Cycle E |

Individual reports containing A2LA Accredited data can be provided |

|

| General Motors |

General Motors GM3607M (12/97) Type I |

Individual reports containing A2LA Accredited data can be provided |

|

| General Motors |

General Motors GM3607M (12/97) Type II |

Individual reports containing A2LA Accredited data can be provided |

|