Product Description:

A 4-mil high initial tack, unsupported acrylic permanent pressure-sensitive film, cast on a silicone-sensitive release liner.

Product Use:

This product was developed for use primarily for Low Surface Energy (LSE) bonding.

Typical Applications include;

- Bonding foam to rigid and flexible plastics

- Laminating and mounting to ABS, powder-coated paints, TPO, PE, PP, PET, and many low-surface energy materials

- Excellent foam bonding properties

- Low VOC bonding applications

Benefits of the high performance LSE Acrylic adhesive:

- Quick initial tack

- Low fogging, low flammability

- High peel and shear properties

- Excellent high and low temperature performance

Adhesive Family

650 High Performance Acrylic Adhesive Adhesive System for LSE bonding

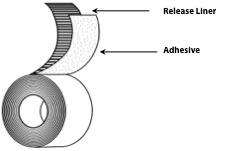

Release Liner

74# White Polycoated Kraft

Carrier/Backing

Not Applicable

Tape Construction

Transfer Tape

Adhesive Liner Side

Acrylic

Adhesive Thickness - Liner Side (Mils)

4.0

Adhesive Exposed Side

Not Applicable

Adhesive Thickness - Exposed Side (Mils)

N/A

Peel Exposed Side

68

Oz/Inch

Note: Typical Values per PSTC #101 Method E, Backed with 1 mil PET. 24 Hour Dwell.

Peel Liner Side

N/A

Oz/Inch

Note: Typical Values per PSTC #101 Method E, Backed with 1 mil PET. 24 Hour Dwell.

Shear Exposed Side

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Shear Liner Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Service Temperature

-30

°F to

375

°F

Note: Data is based on limited testing and under no load.

Roll Weight

Note: Theoretical number only. The actual roll weight may vary.

Tape Thickness (without release liner)

4.0 mils

Note: Theoretical number only. Does not include Release Liner. The actual Tape thickness may vary.

SDS Note: If the specific product is not listed in the appendix of the provided "Article Exemption Letter", please contact your sales/account representative for a SDS.

Bonding Study Results

| Manufacturer |

Material Description | Bonding Result | Notes/Comments |