Product Description:

Product Description:

On the Liner Side 4373M uses an 1.5 mil acrylic adhesive that exhibits outstanding shear and heat resistance properties in addition to forming excellent bonds to a wide variety of substrates. On the Exposed 4373M uses an 1.5 mil acrylic adhesive that exhibits excellent bonds to most polyether and polyester urethane foams.

Product Use:

Forms excellent bonds to a wide variety of ether, ester and low perm urethane foams. Additional utility is found when bonding to closed-cell sponges. The product's polyester carrier provides dimensional stability die cutting operations.

GENERAL USE: 4373 is used in the seal and gasket market and for foams and other materials in the sound attenuation and automotive market. It's elevated temperature resistance makes it ideal for automotive under-hood applications or other high heat environments. Tested and approved to Delphi Automotive SD2-324 for High Temperature Permanent Bonds to 250 deg. F. 4373 is also qualified under several automotive specifications (refer to the Supplemental Product Information Bulletin).

Adhesive Family

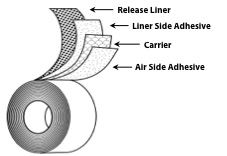

4370 Ultra High Perfomance Foam Bonding Tape System

Release Liner

12pt Natural Polycoated Kraft

Carrier/Backing

1/2 mil Clear Polyester Film

Tape Construction

Double Coated PET Film Tape

Adhesive Liner Side

Acrylic

Adhesive Thickness - Liner Side (Mils)

1.5

Adhesive Exposed Side

Acrylic

Adhesive Thickness - Exposed Side (Mils)

1.5

Peel Exposed Side

150

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell.

Peel Liner Side

160

Oz/Inch

Note: Typical Values per PSTC #101 Method C, Backed with 2 Mil Aluminum Foil. 24 Hour Dwell.

Shear Exposed Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Shear Liner Side

7

days

Note: Typical Values per PSTC #107 Procedure A Modified, 1000 grams/Sq.Inch @ 72oF. No Dwell.

Service Temperature

-40

°F to

250

°F

Note: Data is based on limited testing and under no load.

Roll Weight

0.66 lbs/sq yards

Note: Theoretical number only. The actual roll weight may vary.

Tape Thickness (without release liner)

3.5 mils

Note: Theoretical number only. Does not include Release Liner. The actual Tape thickness may vary.

SDS Note: If the specific product is not listed in the appendix of the provided "Article Exemption Letter", please contact your sales/account representative for a SDS.

Bonding Study Results

| Manufacturer |

Material Description | Bonding Result | Notes/Comments |

Tested Industry Specifications

| Specification Type |

Specification Description |

Notes |

| Chrysler |

Chrysler MS-AY326-C2 |

|

|

| Chrysler |

Chrylser MS-CC211 (Replaced by PF-10770) |

|

|

| Delphi |

Delphi Automotive SD2-324 4.3.4 High Temperature |

|

|

|

|

|

| General Motors |

General Motors GM3622M (11/93) Type IV Cycle E |

|

|

| General Motors |

Modified General Motors 9078; Paragraph 3.1 |

|

|

|

| Toyota |

Toyota Engineering standard TSK5702G |

|

|